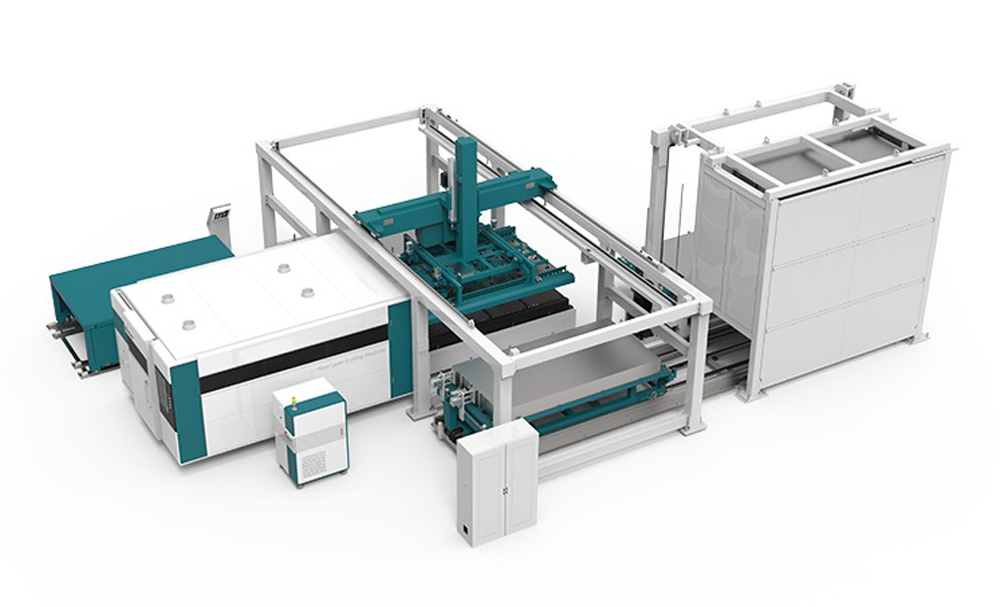

The Fiber Laser cutting machine can be equipped with a single table or with an interchangeable table, which allows us to perform fast transactions in only 12-15 seconds and the cutting processes can be performed simultaneously, resulting in a significant increase in production.

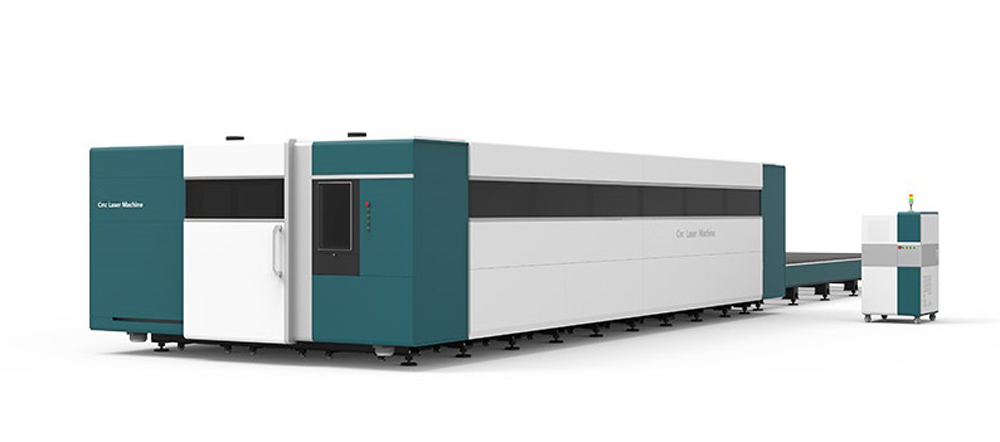

Fiber laser cutting stands out for its high speed, high cutting quality and efficiency. Increases productivity due to its ease of use and low operating costs.

STANDARD EQUIPMENT:

– Dimensions from 600×400 mm up to 40,000 x 2,500 mm. Custom lengths can be manufactured upon request.

– Power ratings from 1 Kw to 40 Kw

– Heavy-duty machine frame

– Aviation aluminum gantry:

It is manufactured to aerospace standards and extrusion molded at 4300 tons of pressure. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as high hardness, very light weight, corrosion resistance, anti-oxidation, low density, and greatly increases the processing speed.

– Laser Generator IPG, Raycus, Max Photonics, etc.

– Precitec, Raytools, etc. cutting head.

– Hardened linear guides

– Ball screw drive

– DELTA Servomotors

– S&A/HANLI/TONGFEI cooling system

– Automatic lubrication